Tel

How manufacturing companies can reduce carbon emission to support the global climate change pledge

COP which stands for Conference of Parties is a summit which has attendees by countries that signed the United Nations Framework Convention on Climate Change (UNFCCC) in 1994 is happening for the 26th time right now (1st week of November 2021) in Glasgow. We are seeing more extreme weather events taking place around the world - including heatwaves, floods and forest fires, these naturally occurring events are being made worse because of the effects of climate change. The past decade was the warmest on record, and governments around the world agree that urgent action is needed.

While governments from around the world are pressured to come up with actionable plans for the future, manufacturing companies will need to proactively pitch in and contribute to reduce carbon emission. Below are some of areas which manufacturing companies can focus on to reduce the greenhouse gas emission. These are some of the practices followed by my Company Tecpacking (which is a prominent machine and material supply to the tea and coffee industry) that can be followed by peer organisations:

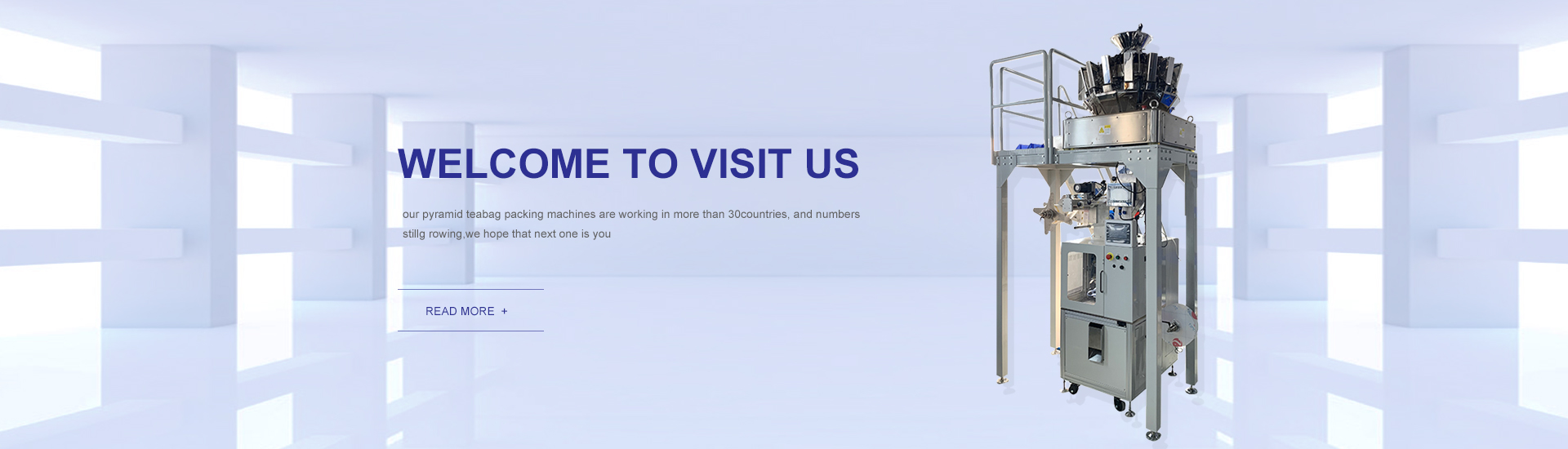

● Invest in quality machines and spares Investing in quality machines would enable a longer life span. This means that there is very less wastage and has a positive impact on the environment. If you consider Tecpacking, the Company places great emphasis on quality and sources raw material only from well recognized quality suppliers from around the world. This enables Tecpacking machines to have very less breakdowns thereby reducing wastage during the lifespan of the machine. This enables less CO2 emission and has a positive impact on the environment.

● Using multi tasking machines Having fewer machines on the go for one project will reduce the amount of energy you require to produce materials or items, which has the double benefit of reducing your business’ energy costs and carbon emissions. It also means you’ll require fewer component parts for multiple machines. Example - cutting processes – which would have traditionally been carried out by multiple machines in one solution.

● Maintaining your equipment effectively Keeping your equipment and its component parts clean and free from debris is an essential step, because this can heavily impact its efficiency. Setting up processes for qualified technicians to regularly review your machinery is essential. Example - Tecpacking has a dynamic support team that helps customers around the world to maintain their machines. This enables the machines to be more efficient and experience less breakdowns.

● Embedding sustainability into your supply chain Ensure your business is sourcing raw materials from sustainable sources. If the businesses you’re sourcing your machinery and raw materials from aren’t sustainable, you may still be indirectly contributing to greenhouse gas emissions. Tecpacking includes sustainability as a key requirement in the tender process, and similar practices should be followed by other Companies as well. As one of the biggest contributors to greenhouse gases, the manufacturing sector has a large role to play. By addressing the machinery and component parts your business uses, including how and where you source them, how you use them, and how you maintain them, you can reduce your emissions to support important environmental causes.

Contact Us

Head office : No. 52-4-501, Liando, Ruike Rd, Shuanggang High-Tech Industry Zone,Tianjin,China

Tel:+86-22-23364133 +86-22-24304649

E-mail:info@tecpacking.com

Copyright © 2020 Tecpacking Group (Tianjin) Co., Ltd. All Rights Reserved. Powered by www.300.cn 津ICP备*********号