Tel

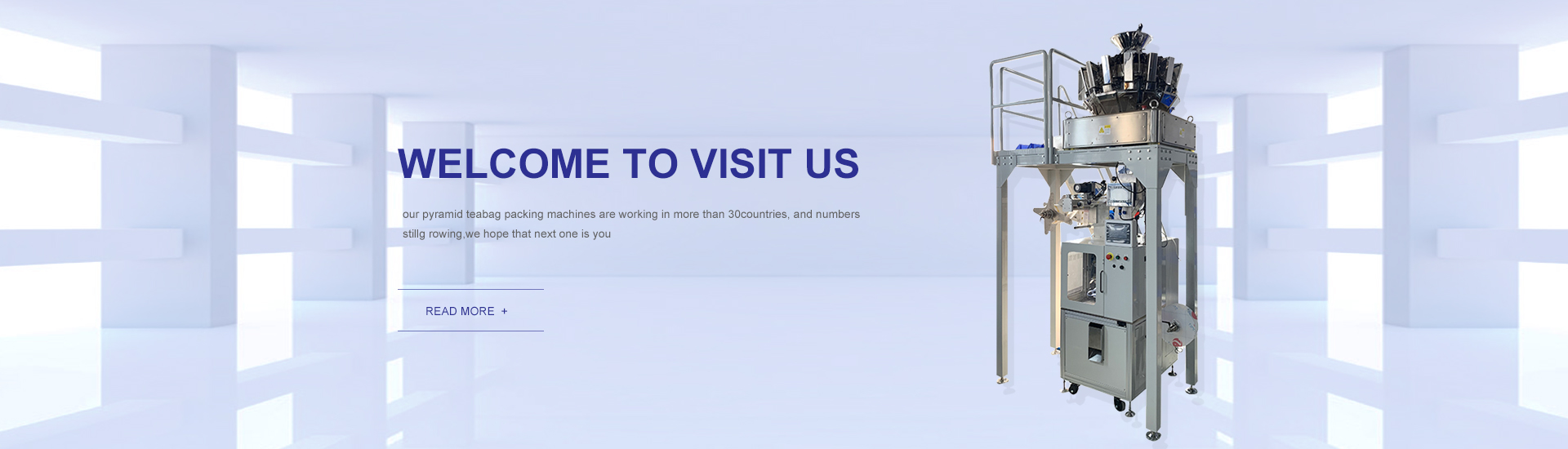

TP-P100 introduction

Application

Technical data

|

Dimensions of machine |

L1844 x W1200 x H2862 mm |

|

Overall Dimensions with working platform |

L1844 x W2900x H2862 mm |

|

Weight |

1500kg |

|

Power |

220V 50HZ 1P Max. 3kw |

|

Operating Pressure and Consumption |

6 bars, 150l/min (12mm air pipe) |

|

Sealing type |

Ultrasonic sealing |

|

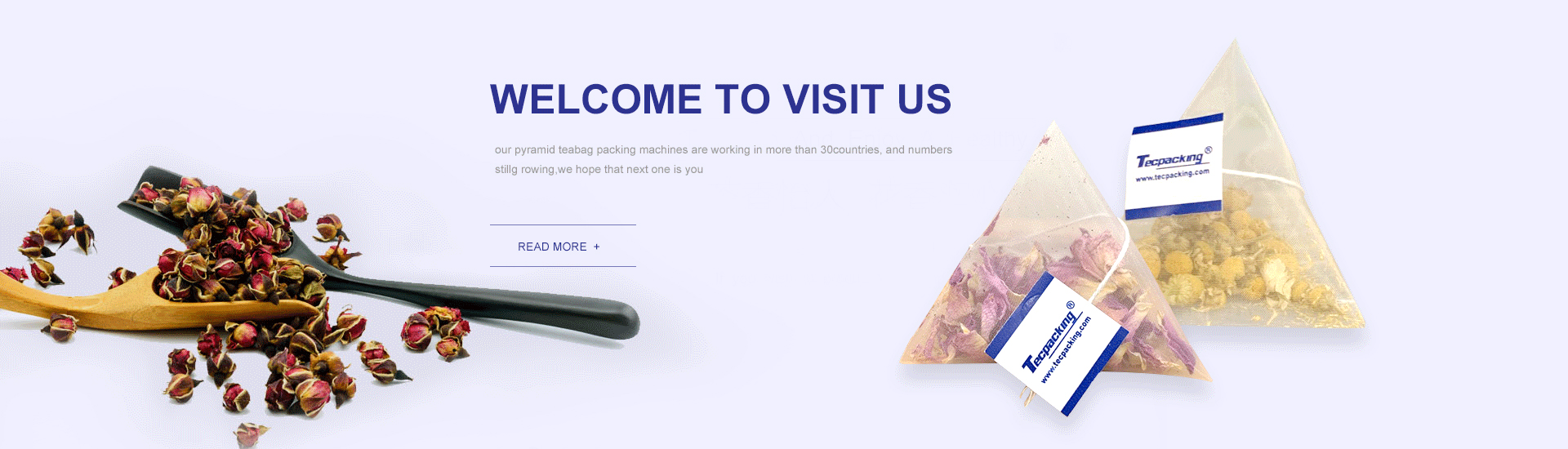

Bag type |

Pyramid bag/flat bag |

|

Material |

Nylon, PET, Non-Woven Fabric, PLA... etc. (ultrasonic sealing filter/mesh) |

|

Filter Width |

120-180mm |

|

Tea Bag Size |

Triangular: 50–80 mm (each edge) |

|

Capacity |

90-100 bags/min |

Component

|

PLC |

SIMENS S7-1200 |

Germany |

|

Proximity switch |

OMRON |

Japan |

|

photocell |

Panasonic |

Japan |

|

Servo driver |

Delta |

Taiwan, China |

|

Servo motor |

Delta |

Taiwan, China |

|

Stepper motor |

MOONS’ |

China |

|

Stepper driver |

MOONS’ |

China |

|

Circuit breaker |

ABB |

Switzerland |

|

Button |

ABB |

Switzerland |

|

Relay |

ABB |

Switzerland |

|

Photocoupler |

Weidmuller |

Germany |

|

Main switch |

Schneider |

France |

|

Limit switch |

OMRON |

Japan |

|

Door safety switch |

OMRON |

Japan |

|

Touch panel |

Kinco |

China |

|

Solenoid valve |

SMC |

Japan |

|

Cylinder |

SMC |

Japan |

|

Power supply |

MEAN WELL/ OMRON |

Germany/Japan |

Safety

According to Europe standard production, all electrical parts are grounded to prevent electricity danger, electrical cabinet waterproof grade IP54, all parts of the machine are affixed with standard safety production sign

The machine can be stopped by safety relay when the safety circuit is out of order, the machine can not be started again, which can guarantee the safety of the operator and the machine

When the safety door is opening,the machine automatically stop, cylinder pressure relief: Emergency Stop the machine, the horizontal sealing system automatically relieve pressure, to avoid accident.

SMART & Easy to use

A key to control the machine, all functions automatically start, automatically identify the film tagged or not tag.

The machine does not work for more than 10 seconds, and the ultrasonic sealing system shuts off automatically

When the failure occurs, the PLC automatically shows the part of the failure. After adjust the machine, press the trouble-clearing key and the machine automatically resets to continue working

Production data can be pre-set

Can set up shift production

Adjustable speed

erase all content and settings

High Speed & Stability

Packing speed is 90-100bags/min which is 80% more efficient than other machines

14 heads scale weighing, easy to set, accuracy 0.1 g,

Production progress of equipment and various functions can be visualized in PLC.

Exceeding weight tea directly kick out, no wasting of material

Waste collector, reduce noise and save compressed air.

Characteristics

It adopts a special sensor with high precision and high standard resolution

Ex-factory parameters set recovery function, support multi-segment weight calibration

When the material is short of, it can be stopped automatically to make the weighing more stable

Storage of 100 sets of parameters to achieve a variety of material requirements, help menu, easy to learn to use

The amplitude of each line can be adjusted independently in operation to make feeding more even

A variety of languages available, easy to operate, suitable for the global market

ultra-small 0.3 L hopper, adopt ultra-low vibration design, run more smoothly, weighing accuracy is higher

The new double parallel line vibration machine vibrates less, the side drive type aluminum box reading is more accurate, the weighing precision is higher

Weighing-type material detection, accurate control filling time, material thickness, ensure weighing accuracy

Special v-shaped vibrating plate, small weight weighing design, ensure filling uniformity and weighing accuracy

The integral case and center seat increase the strength of the machine, making the hopper stable for a shorter time

Aftersale service

1. Free packaging solution consultancy.

2. Customization service.

3. Fast reply within 12 hours

4. A life-long time of technical support to the machine.

5. Spare parts delivered withing 3-5 working days

6. Free installation and technical training.

Leave a message

Contact Us

Head office : No. 52-4-501, Liando, Ruike Rd, Shuanggang High-Tech Industry Zone,Tianjin,China

Tel:+86-22-23364133 +86-22-24304649

E-mail:info@tecpacking.com

Copyright © 2020 Tecpacking Group (Tianjin) Co., Ltd. All Rights Reserved. Powered by www.300.cn 津ICP备*********号